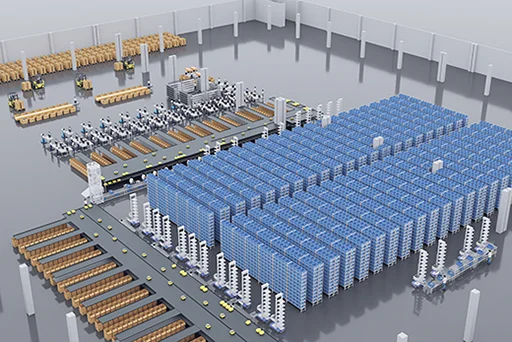

Goods-to-Person Robotics System Overview

The landscape of order fulfillment is constantly evolving, driven by fluctuations in consumer demand, seasonal spikes, and the growing trend of e-commerce. Traditional fulfillment methods struggle to keep pace with these changes, often leading to inefficiencies and increased labor costs. Goods-to-person systems, enhanced by robotics, offer a flexible and scalable solution to adapt to these varying demands, ensuring consistent performance even during peak periods.

Integrating robots into goods-to-person order fulfillment picking systems significantly transforms the role of human labor. Instead of walking long distances to retrieve items, workers are stationed at ergonomic workstations where robots bring the goods to them. This collaboration between robots and human workers enhances efficiency, reduces physical strain, and allows human labor to focus on tasks that require complex decision-making and problem-solving skills. Furthermore, it helps mitigate labor shortages by automating repetitive and time-consuming tasks.