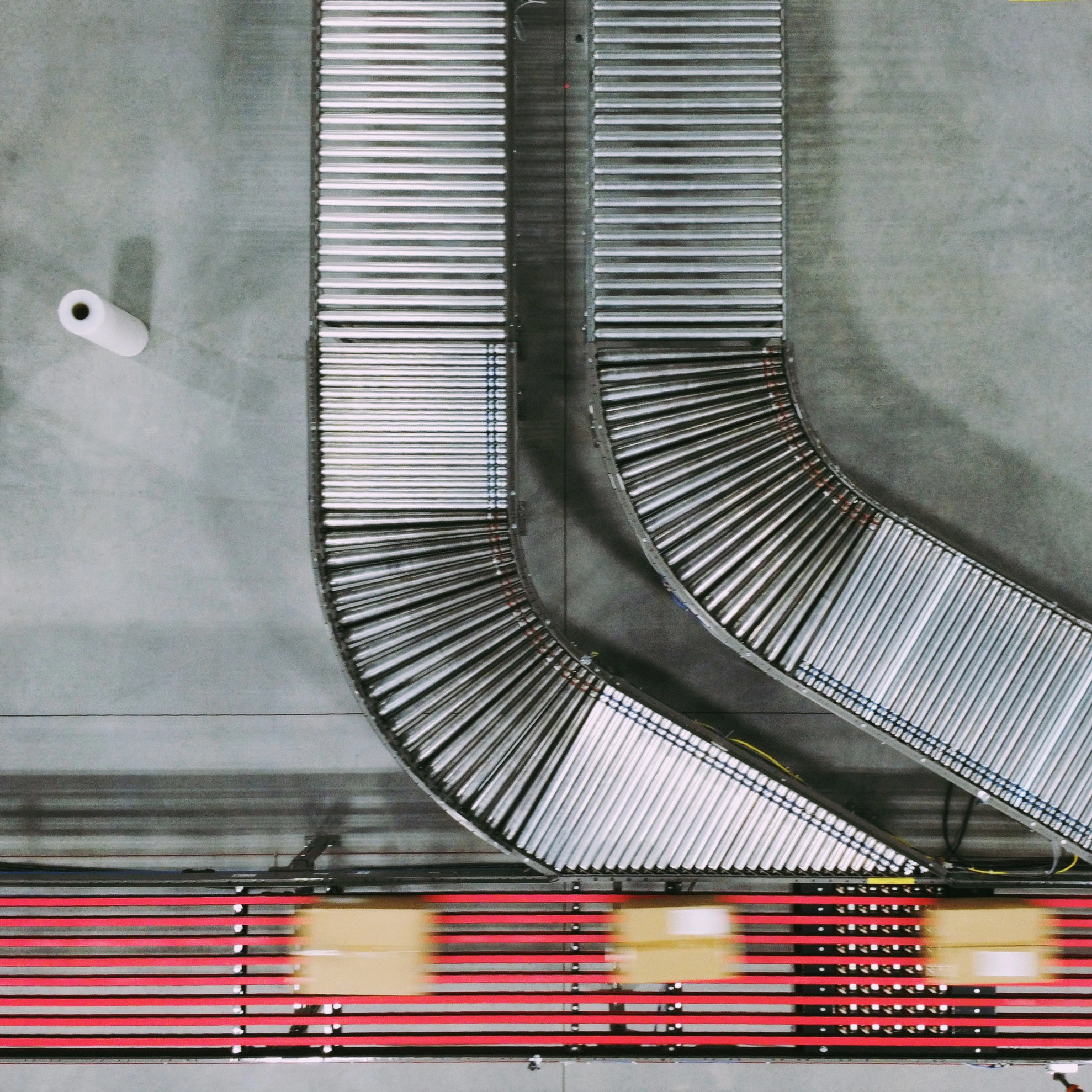

Custom conveyor design, installation, and long-term support

We design, install, and support conveyor systems that keep products moving and reduce manual work.

A well-planned conveyor system is built around your products and process. We start by reviewing how cartons, totes, pallets, or items move through your building, from receiving and put-away to picking, packing, and shipping. Based on that, we design a system that helps reduce touches, limits lifting, and cut down on long walking paths. Our team of professionals brings many years of real-world experience to every project, which helps ensure your system works as expected under daily demand.

Our team matches the conveyor style to your products, making sure it can handle the size, weight, and packaging you use in daily operations.

Installation is handled by experienced crews who understand the detail involved in setting elevation, line flow, and transitions between equipment. We also account for seismic requirements, making sure anchoring, bracing, and structural supports meet the standards for your region. Once the conveyor is in place, we can integrate sensors, controls, and other devices as part of a larger system or as a standalone line.

To help you track and service your equipment over time, we offer QR labeling and tracking. This gives your team a quick way to reference specific sections of conveyor, look up parts information, and request service.

For select conveyor brands, we offer a customer portal where you can order spare and replacement parts. This makes it easier to keep common components on hand so small issues do not turn into extended downtime.

Support and uptime are top priorities. Our goal is to keep your system running, reduce downtime, and make sure your operation stays productive long after installation day.